Отделение углеродных наноструктур

Заведующий отделением - д.х.н. Мордкович Владимир ЗальмановичОтделение было основано доктором химических наук, Лауреатом премии Сасаки (Япония, 2002г.) за достижения в области перспективных материалов, Мордковичем Владимиром Зальмановичем.

Направления работ

Отделение создано в 2009 году (как отдел новых химических технологий и наноматериалов) для проведения научно- исследовательских работ и прикладных разработок в области химических методов создания наноструктур и технологии применения наноматериалов.

Цели деятельности - разработка научных основ производства волокон, катализаторов, керамических и гибридных материалов на основе сверхдлинных углеродных нанотрубок и фуллеритов для машиностроения, энергетики, химической промышленности и медицинской промышленности. Также разработка научных основ химической технологии с применением основанных на таких композитах устойчивых и высокотеплопроводных катализаторов химических/нефтехимических процессов, электродных и вспомогательных материалов повышенной эффективности/емкости для инновационных накопителей и генераторов энергии (суперконденсаторы, металл-ионные аккумуляторы, топливные элементы), сверхлегких неметаллических проводящих кабелей, анизотропных радиопоглощающих покрытий с использованием резонирующих ориентированных пучков нанотрубок, биологически нейтральных медицинских сенсоров и т.д.

Научная деятельность отделения направлена на выявление качественных отличий между классическими углеграфитовыми материалами, с одной стороны, и метаматериалами на основе углеродных наноструктур

Отделение ведет подготовку кадров высшей квалификации: подготовлено 27 кандидатов и 1 доктор наук

Методы

В отделении проводятся как экспериментальные работы, так и математическое моделирование процессов. Ведется создание комплекса экспериментальных установок, предназначенных для:

- синтеза наноструктур химическими методами, в том числе методом CVD;

- исследования каталитических свойств наноструктур в процессах, важных для химической технологии;

- исследования электрохимических свойств наноструктур в процессах накопления энергии;

- исследования взаимодействия углеродных наноструктур с электромагнитным излучением;

- исследования термических, поверхностных и адсорбционных свойств синтезированных наноструктур; получения композитных материалов на основе синтезированных наноструктур.

Научные исследования проводятся в отделении по трем тесно связанным направлениям, - соответственно, в трех научно-исследовательских лабораториях:

ОСНОВНЫЕ ДОСТИЖЕНИЯ

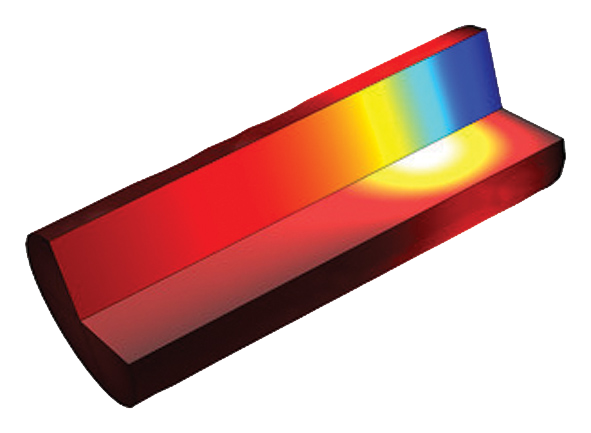

Семейство углеродсодержащих катализаторов с аномально высокой теплопроводностью

Уникальная структура с щелевой пористостью

Две марки катализатора поставлены на промышленное производство

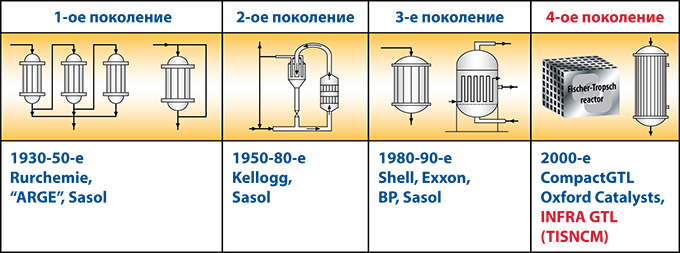

Технология синтетического топлива разработана и масштабирована в промышленный масштаб

Гранулированный катализатор |

Рост УНТ в кварцевом реакторе |

Материалы для электрохимических накопителей энергии

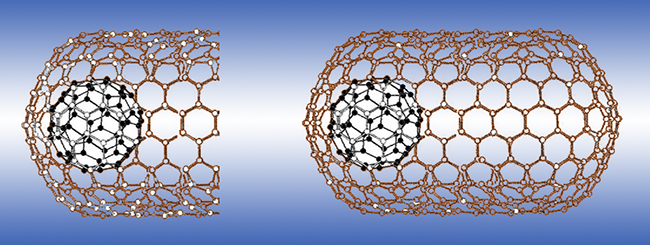

Сверхдлинные углеродные нанотрубки - синтез в непрерывном процессе, получение в виде бобины (текстильной шпули)

Неподдержанные легкие электроды из нанотрубок для суперконденсаторов

Плотная электропроводящая бумага из нанотрубок для топливных элементов и редокс-батарей

Гибридные углеродные материалы для анодов металл-ионных аккумуляторов

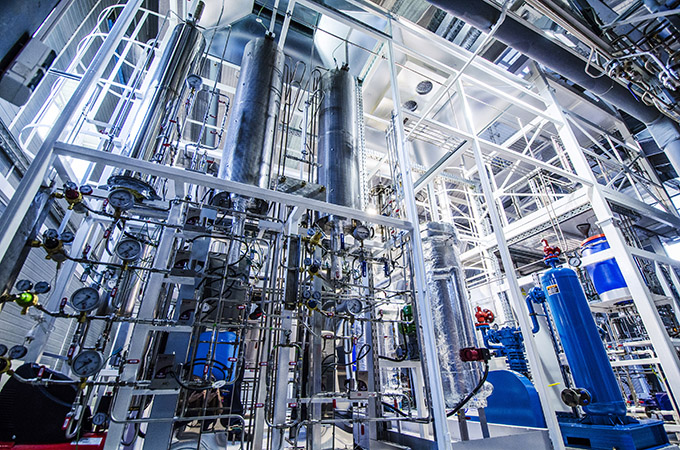

Опытно-промышленная установка синтетических жидких топлив |

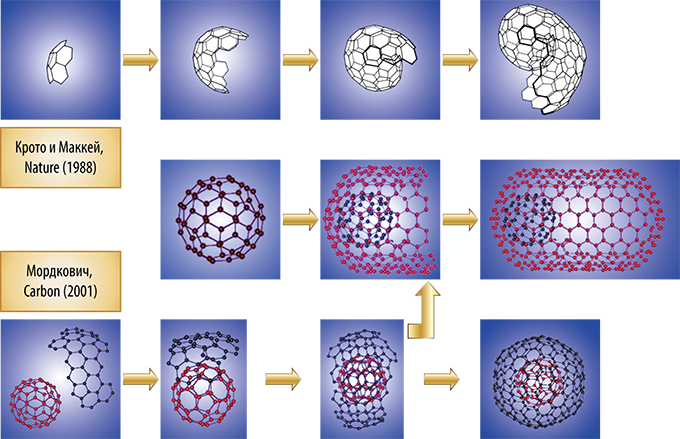

Механизмы роста многослойных структур

Отклонение от нормального механизма –

укороченные структуры вместо нанотрубок

Современные возможности моделирования гетерогенных каталитических

процессов и основные направления современного развития

Развитие технологии синтеза Фишера-Тропша

Публикации

- 2023 Cobalt-zeolite Fischer–Tropsch catalysts with different types of aluminum metal powder

Asalieva E.Yu, Sineva L.V., Mordkovich V.Z.

в журнале Известия высших учебных заведений. Химия и химическая технология, издательство Иван. химико-технол. ун-т (Иваново), том 66, № 10, с. 44-51 DOI - 2023 Influence of Pre-Carburization on Performance of Industrial Cobalt-Based Pelletized Fischer–Tropsch Catalyst

Mordkovich Vladimir, Gryaznov Kirill, Sineva Lilia, Asalieva Ekaterina, Gorshkov Andrei, Mitberg Eduard

в журнале Catalysts, том 13, № 8 DOI - 2023 Кобальт-цеолитные катализаторы синтеза Фишера–Тропша, содержащие металлический алюминий различных типов

Асалиева Е.Ю., Синева Л.В., Мордкович В.З.

в журнале Известия высших учебных заведений. Химия и химическая технология, издательство Иван. химико-технол. ун-т (Иваново), том 66, № 10, с. 44-51 DOI - 2023 Zeolite-Containing Co Catalysts for Fischer–Tropsch Synthesis with Tailor-Made Molecular-Weight Distribution of Hydrocarbons

Sineva Lilia, Mordkovich Vladimir, Asalieva Ekaterina, Smirnova Valeria

в журнале Reactions, издательство MDPI (Basel, Switzerland), том 4, № 3, с. 359-380 DOI - 2023 Deactivation and Regeneration of a Zeolite-Containing Cobalt Catalyst in a Fisher–Tropsch Synthesis Reactor

Gorshkov A.S., Sineva L.V., Gryaznov K.O., Asalieva E.Yu, Mordkovich V.Z.

в журнале Catalysis in Industry, том 15, № 2, с. 152-164 DOI - 2023 Одно-, дву- и многостенные углеродные нанотрубки как электропроводящие добавки в катоды литий-ионных аккумуляторов

Бабкин А.В., Кубарьков А.В., Дрожжин О.А., Урванов С.А., Филимоненков И.С., Ткачев А.Г., Мордкович В.З., Сергеев В.Г., Антипов Е.В.

в журнале Доклады Российской академии наук. Химия, науки о материалах, издательство Российская академия наук (Москва), том 508, № 1, с. 1-9 - 2023 Single-, Double-, and Multi-Walled Carbon Nanotubes as Electrically Conductive Additives to Lithium-Ion Battery Cathodes

Babkin A.V., Kubarkov A.V., Drozhzhin O.A., Urvanov S.A., Filimonenkov I.S., Tkachev A.G., Mordkovich V.Z., Sergeyev V.G., Antipov E.V.

в журнале Doklady Chemistry, издательство Pleiades Publishing, Ltd (Road Town, United Kingdom), том 508, № 1, с. 1-9 DOI - 2023 Современное состояние технологии XTL на основе синтеза Фишера–Тропша: основные направления развития

Асалиева Е.Ю., Синева Л.В., Мордкович В.З.

в журнале Научный журнал Российского газового общества, издательство Союз организаций нефтегазовой отрасли "Российское газовое общество" (Москва), том 39, № 3, с. 64-71 - 2023 Comprehensive Comparison of High-Performance Fischer-Tropsch Synthesis Cobalt Catalysts Containing Different Types of Heat-Conducting Frames

Gryaznov K.O., Sineva L.V., Asalieva E.Yu, Mordkovich V.Z.

в журнале Catalysis in Industry, том 15, № 1, с. 21-35 DOI - 2023 The Importance of Water for Purification of Longer Carbon Nanotubes for Nanocomposite Applications

Mordkovich Vladimir Z., Khaskov Maxim A., Naumova Veronika A., De Victor V., Kulnitskiy Boris A., Karaeva Aida R.

в журнале Journal of Composites Science, издательство MDPI (Basel, Switzerland), том 7, № 2, с. 79-89 DOI - 2023 Wet oxidative functionalization of carbon nanotube cloth to boost its performance as a flexible supercapacitor electrode

Filimonenkov Ivan S., Urvanov Sergey A., Kazennov Nikita V., Karaeva Aida R., Skryleva Elena A., Solomonik Igor G., Batova Natalya I., Kurzhumbaev Didar Zh, Tsirlina Galina A., Mordkovich Vladimir Z.

в журнале Electrochimica Acta, издательство Elsevier BV (Netherlands), том 437 DOI - 2022 Особенности дезактивации и регенерации цеолитсодержащего кобальтового катализатора в реакторе синтеза Фишера–Тропша

Горшков А.С., Синева Л.В., Грязнов К.О., Асалиева Е.Ю., Мордкович В.З.

в журнале Катализ в промышленности /CATALYSIS IN INDUSTRY, том 22, № 6, с. 16-29 - 2022 Carbon nanotube cloth as a promising electrode material for flexible aqueous supercapacitors

Filimonenkov Ivan S., Urvanov Sergey A., Kazennov Nikita V., Tarelkin Sergey A., Tsirlina Galina A., Mordkovich Vladimir Z.

в журнале Journal of Applied Electrochemistry, издательство Springer Nature (Switzerland) DOI - 2022 Комплексное сравнение высокопроизводительных кобальтовых катализаторов синтеза Фишера–Тропша, содержащих теплопроводящие скелеты разных типов

Грязнов К.О., Синева Л.В., Асалиева Е.Ю., Мордкович В.З.

в журнале Катализ в промышленности, издательство Калвис (М.), том 22, № 4, с. 6-21 DOI - 2022 Preparation of Raney cobalt and identification of surface structures responsible for catalytic activity in the Fischer–Tropsch process

Solomonik I.G., Gryaznov K.O., Mitberg E.B., Mordkovich V.Z.

в журнале APPLIED BIOLOGICAL RESEARCH DOI - 2022 Cathodic deposition of manganese oxide for fabrication of hybrid recharging materials based on flexible CNT cloth

Pugolovkin Leonid V., Levin Eduard E., Arkharova Natalia A., Orekhov Anton S., Urvanov Sergey A., Mordkovich Vladimir Z., Tsirlina Galina A.

в журнале Electrochimica Acta, издательство Elsevier BV (Netherlands), том 412 DOI - 2022 Carbon nanotube cloth as a promising electrode material for flexible aqueous supercapacitors

Filimonenkov Ivan S., Urvanov Sergey A., Kazennov Nikita V., Tarelkin Sergey A., Tsirlina Galina A., Mordkovich Vladimir Z.

в журнале Journal of Applied Electrochemistry, издательство Springer Nature (Switzerland) DOI - 2021 Особенности каталитических превращений углеводородов на цеолитах при температурах 170–260°С

Горохова Е.О., Кульчаковская Е.В., Асалиева Е.Ю., Грязнов К.О., Митберг Э.Б., Синева Л.В., Мордкович В.З.

в журнале Современные молекулярные сита, том 3, № 1, с. 112-118 DOI - 2021 Catalytic Conversions of Hydrocarbons over Zeolites at 170–260°C

Gorokhova E.O., Kulchakovskaya E.V., Asalieva E.Yu, Gryaznov K.O., Mitberg E.B., Sineva L.V., Mordkovich V.Z.

в журнале Petroleum Chemistry, издательство Pleiades Publishing, Ltd (Road Town, United Kingdom), том 61, № 3, с. 357-363 DOI - 2021 Epoxy Nanocomposites with Carbon Nanotubes Produced by Floating Catalyst CVD

Mordkovich Vladimir Z., Kondrashov Stanislav V., Karaeva Aida R., Urvanov Sergey A., Kazennov Nikita V., Mitberg Eduard B., Pushina Ekaterina A.

в журнале Nanomaterials, издательство MDPI (Basel, Switzerland), том 11, № 5, с. 1213-1213 DOI - 2021 Zeolites as a tool for intensification of mass transfer on the surface of a cobalt Fischer–Tropsch synthesis catalyst

Sineva Lilia V., Gorokhova Ekaterina O., Gryaznov Kirill O., Ermolaev Ilya S., Mordkovich Vladimir Z.

в журнале Catalysis Today, издательство Elsevier BV (Netherlands) DOI - 2020 Исследование структурных и физических свойств композиционного носителя катализатора с применением терморасширенного графита

Pushina E.A., Karaeva A.R., Solomonik I.G., Urvanov S.А., Mordkovich V.Z.

в журнале Advanced Materials and Technologies, издательство Тамбовский государственный технический университет (Тамбов), № 2(18), с. 019-024 DOI - 2020 A Superhydrophobic Coating Based on Onion-Like Carbon Nanoparticles

Eseev M.K., Kapustin S.N., Lugvishchuk D.S., Mordkovich V.Z., Lyakh N.L.

в журнале Technical Physics Letters, издательство Pleiades Publishing, Ltd (Road Town, United Kingdom), том 46, № 11, с. 1120-1123 DOI - 2020 Water-Zeolite Interfaces for Controlling Reaction Routes in Fischer- Tropsch Synthesis of Alternative Fuels

Mordkovich Vladimir Z., Sineva Lilia V.

в журнале Current Catalysis, издательство Bentham Science Publishers (Netherlands), том 9, № 1, с. 3-22 DOI - 2020 The Fischer – Tropsch synthesis with a cobalt catalyst on titania-doped silicon carbide

Solomonik I.G., Gorshkov A.S., Mordkovich V.Z.

в журнале Catalysis in Industry, том 12, № 3, с. 235-243 DOI - 2020 Effect of Zeolite on Fischer–Tropsch Synthesis in the Presence of a Catalyst Based on Skeletal Cobalt

Asalieva E.Yu, Kul’chakovskaya E.V., Sineva L.V., Mordkovich V.Z.

в журнале Petroleum Chemistry, издательство Pleiades Publishing, Ltd (Road Town, United Kingdom), том 60, № 1, с. 69-74 DOI - 2020 Свойства и перспективы практического использования дизельной фракции легкой синтетической нефти, полученной методом Фишера-Тропша

Колобков Б.И., Лунева В.В., Ощенко А.П., Губарева В.А., Черных А.В., Мордкович В.З., Митберг Э.Б., Нехаев А.И.

в журнале Нефтепереработка и нефтехимия, № 6, с. 6-11 - 2020 ОСОБЕННОСТИ УГЛЕРОДНЫХ НАНОТРУБОК, ПОЛУЧЕННЫХ В ПРИСУТСТВИИ МЕТАЛЛОЦЕНОВ ЭЛЕМЕНТОВ VIII ГРУППЫ

Караева А.Р., Урванов С.А., Казеннов Н.В., Митберг Э.Б., Мордкович В.З.

в журнале Известия высших учебных заведений. Химия и химическая технология, издательство Иван. химико-технол. ун-т (Иваново), том 63, № 12, с. 4-9 DOI - 2020 СОЗДАНИЕ И ИССЛЕДОВАНИЕ ЭПОКСИНАНОКОМПОЗИТОВ С УГЛЕРОДНЫМИ НАНОТРУБКАМИ, ПОЛУЧЕННЫМИ МЕТОДОМ ФЛОАТ-КАТАЛИЗА

Мордкович В.З., Кондрашов С.В., Караева А.Р., Казеннов Н.В., Урванов С.А., Пушина Е.А., Загора А.Г., Антюфеева Н.В.

в журнале Известия высших учебных заведений. Химия и химическая технология, издательство Иван. химико-технол. ун-т (Иваново), том 63, № 12, с. 22-27 DOI - 2020 СКЕЛЕТНЫЙ КОБАЛЬТ ДЛЯ ПОЛУЧЕНИЯ УГЛЕВОДОРОДОВ В СИНТЕЗЕ ФИШЕРА-ТРОПША

Соломоник И.Г., Грязнов К.О., Митберг Э.Б., Мордкович В.З.

в журнале Известия высших учебных заведений. Химия и химическая технология, издательство Иван. химико-технол. ун-т (Иваново), том 63, № 12, с. 71-76 DOI - 2020 Сверхгидрофобное покрытие из углеродных наночастиц луковичной структуры

Есеев М.К., Капустин С.Н., Лугвищук Д.С., Мордкович В.З., Лях Н.Л.

в журнале Письма в "Журнал технической физики", издательство Физико-технический институт им. А.Ф.Иоффе Российской академии наук (Москва), том 46, № 22, с. 19-19 DOI - 2020 Investigation of structural and physical properties of composite catalyst support with exfoliated graphite additive

Pushina E.A., Karaeva A.R., Solomonik I.G., Urvanov S.А., Mordkovich V.Z.

в журнале Advanced Materials and Technologies, издательство Тамбовский государственный технический университет (Тамбов), том 2, № 18, с. 19-24 DOI - 2020 Exfoliated graphite as a heat-conductive frame for a new pelletized Fischer–Tropsch synthesis catalyst

Asalieva Ekaterina, Sineva Lilia, Sinichkina Svetlana, Solomonik Igor, Gryaznov Kirill, Pushina Ekaterina, Kulchakovskaya Ekaterina, Kulnitskiy Boris, Ovsyannikov Danila, Mordkovich Vladimir

в журнале Applied Catalysis A: General, издательство Elsevier BV (Netherlands), том 601, с. 117639-117639 DOI - 2020 Synthesis, Structure and Electrical Resistivity of Carbon Nanotubes Synthesized over Group VIII Metallocenes

Karaeva Aida, Urvanov Sergey, Kazennov Nikita, Mitberg Eduard, Mordkovich Vladimir

в журнале Nanomaterials, издательство MDPI (Basel, Switzerland), том 10, № 11, с. 2279-2279 DOI - 2020 Experimental Study of the Fischer–Tropsch Synthesis Using Nitrogen-Containing Syngas and Variable Pressure

Gorshkov A.S., Ermolaev I.S., Gryaznov K.O., Mitberg E.B., Sineva L.V., Solomonik I.G., Mordkovich V.Z.

в журнале Катализ в промышленности, издательство Калвис (М.), том 20, № 5, с. 381-390 DOI - 2020 Cubic and tetragonal maghemite formation inside carbon nanotubes under chemical vapor deposition process conditions

Kulnitskiy B.A., Mordkovich V.Z., Karaeva A.R., Urvanov S.A., Blank V.D.

в журнале Fullerenes, Nanotubes and Carbon Nanostructures, издательство Taylor & Francis (United Kingdom), том 28, № 11, с. 913-918 DOI - 2020 Irreversible high pressure phase transformation of onion-like carbon due to shell confinement

Lugvishchuk Dmitry S., Mitberg Edward B., Kulnitskiy Boris A., Skryleva Elena A., Parkhomenko Yury N., Popov Mikhail Yu, Churkin Valentin D., Mordkovich Vladimir Z.

в журнале Diamond and Related Materials, издательство Elsevier BV (Netherlands), том 107, с. 107908 DOI - 2020 Cинтез Фишера – Тропша c кобальтовым катализатором на модифицированном оксидом титана карбиде кремния

Solomonik I.G., Gorshkov A.S., Mordkovich V.Z.

в журнале Катализ в промышленности, издательство Калвис (М.), том 20, № 2, с. 100-109 DOI - 2020 Cooperative effect of cobalt and zeolite in controlling activity and stability of a catalytic Fischer–Tropsch process

Sineva Liliya V., Asalieva Ekaterina Yu, Kulchakovskaya Ekaterina V., Gryaznov Kirill O., Mordkovich Vladimir Z.

в журнале APPLIED PETROCHEMICAL RESEARCH, том 10, № 1, с. 13-20 DOI - 2020 Влияние цеолита на синтез Фишера–Тропша в присутствии катализатора на основе скелетного кобальта

Асалиева Е.Ю., Кульчаковская Е.В., Синева Л.В., Мордкович В.З.

в журнале Нефтехимия, том 60, № 1, с. 76-82 DOI - 2020 Synergistic effect in Co–zeolite catalyzed transformations of hydrocarbons under Fischer–Tropsch conditions

Sineva Lilia V., Gorokhova Ekaterina O., Kulchakovskaya Ekaterina V., Asalieva Ekaterina Yu, Pushina Ekaterina A., Kirichenko Alexey N., Mordkovich Vladimir Z.

в журнале Mendeleev Communications, издательство Elsevier BV (Netherlands), том 30, № 2, с. 198-201 DOI - 2020 Hydrocarbon transformations on Co–zeolite in catalytic environment of different redox properties at 170–260 °C

Sineva Lilia V., Gorokhova Ekaterina O., Pushina Ekaterina A., Kulchakovskaya Ekaterina V., Mordkovich Vladimir Z.

в журнале Mendeleev Communications, издательство Elsevier BV (Netherlands), том 30, № 3, с. 362-365 DOI - 2019 Natural gas partial oxidation process as a way to synthesize onion-like carbon

Lugvishchuk Dmitry S., Mordkovich Vladimir Z., Mitberg Edward B., Karaeva Aida R., Kulnitskiy Boris A., Kirichenko Alexei N., Polyakov Sergei N.

в журнале Fullerenes, Nanotubes and Carbon Nanostructures, издательство Taylor & Francis (United Kingdom), том 28, № 4, с. 250-255 DOI - 2019 TEM studies of conical scroll carbon nanotubes formed by aerosol synthesis

Kulnitskiy B., Karaeva A., Mordkovich V., Urvanov S., Bredikhina A.

в журнале IOP Conference Series: Materials Science and Engineering, издательство - (Krakow), том 693, с. 012017 DOI - 2019 ПЕРСПЕКТИВНЫЕ ТЕНДЕНЦИИ В КАТАЛИЗЕ ГАЗОХИМИЧЕСКИХ ПРОЦЕССОВ: КОБАЛЬТОВЫЕ КАТАЛИЗАТОРЫ СИНТЕЗА ФИШЕРА–ТРОПША. ЧАСТЬ 2

Синева Л.В., Мордкович В.З.

в журнале Научный журнал Российского газового общества, издательство Союз организаций нефтегазовой отрасли "Российское газовое общество" (Москва), том 2, № 21, с. 56-68 - 2019 ПЕРСПЕКТИВНЫЕ ТЕНДЕНЦИИ В КАТАЛИЗЕ ГАЗОХИМИЧЕСКИХ ПРОЦЕССОВ: КОБАЛЬТОВЫЕ КАТАЛИЗАТОРЫ СИНТЕЗА ФИШЕРА–ТРОПША. ЧАСТЬ 1

Синева Л.В., Мордкович В.З.

в журнале Научный журнал Российского газового общества, издательство Союз организаций нефтегазовой отрасли "Российское газовое общество" (Москва), том 1, № 20, с. 42-57 - 2019 Method for recovery of complete molecular composition of the Fischer-Tropsch synthesis products on the basis of incomplete experimental data

Ermolaev Vadim S., Mordkovich V.Z.

в журнале Chemical Engineering Science, издательство Pergamon Press Ltd. (United Kingdom), том 197, с. 317-325 DOI - 2018 Formation of concentric shell carbon by homogeneous partial oxidation of methane

Mordkovich V.Z., Lugvishchuk D.S., Mitberg E.B., Kulnitskiy B.A., Perezhogin I.A., Kirichenko A.N.

в журнале Chemical Physics Letters, издательство Elsevier BV (Netherlands), том 713, с. 242-246 DOI - 2018 Longer carbon nanotubes with low impurity level

Zhukova Ekaterina A., Urvanov Sergey A., Karaeva Aida R., Kazennov Nikita V., Mordkovich Vladimir Z.

в журнале Materials Today, издательство Elsevier BV (Netherlands), том 5, № 12, с. 25948-25950 DOI - 2018 Carbon nanotubes by continuous growth, pulling and harvesting into big spools

Karaeva Aida R., Kazennov Nikita V., Zhukova Ekaterina A., Mordkovich Vladimir Z.

в журнале Materials Today, издательство Elsevier BV (Netherlands), том 5, № 12, с. 25951-25955 DOI - 2018 Nanostructured aluminum-matrix composite materials with controlled reactivity, modified by carbon and transition metals

Evdokimov Ivan A., Khayrullin Rinat R., Urvanov Sergei A., Perfilov Sergei A., Pozdnyakov Andrey A., Mordkovich Vladimir Z., Blank Vladimir D.

в журнале Materials Today, издательство Elsevier BV (Netherlands), том 5, № 12, с. 26133-26139 DOI - 2018 Синтетическое топливо: четыре поколения технологии

Мордкович В.З.

в журнале Oil&Gas Journal Russia, № 10 (130), с. 70-77 - 2018 Carbon nanotube cloth for electrochemical charge storage in aqueous media

Filimonenkov Ivan S., Urvanov Sergey A., Zhukova Ekaterina A., Karaeva Aida R., Skryleva Elena A., Mordkovich Vladimir Z., Tsirlina Galina A.

в журнале Journal of Electroanalytical Chemistry, издательство Elsevier Sequoia (Switzerland), том 827, с. 58-63 DOI - 2018 Разработка и результаты испытаний альтернативных высокооктановых автомобильных топлив

Потанин Д.А., Ершов М.А., Капустин В.М., Гусева А.И., Гуляева Л.А., Мордкович В.З., Григорьева Е.В.

в журнале Нефтепереработка и нефтехимия, № 7, с. 7-11 - 2018 Soot Formation in the Methane Partial Oxidation Process under Conditions of Partial Saturation with Water Vapor

Lugvishchuk D.S., Kulchakovsky P.I., Mitberg E.B., Mordkovich V.Z.

в журнале Petroleum Chemistry, издательство Pleiades Publishing, Ltd (Road Town, United Kingdom), том 58, № 5, с. 427-433 DOI - 2018 САЖЕОБРАЗОВАНИЕ В ПРОЦЕССЕ ВЫСОКОТЕМПЕРАТУРНОГО ПАРЦИАЛЬНОГО ОКИСЛЕНИЯ МЕТАНА В УСЛОВИЯХ ЧАСТИЧНОЙ САТУРАЦИИ ПАРАМИ ВОДЫ

Лугвищук Д.С., Кульчаковский П.И., Митберг Э.Б., Мордкович В.З.

в журнале Нефтехимия, том 58, № 3, с. 324-331 DOI - 2018 Heat and mass transfer in Fischer–Tropsch catalytic granule with localized cobalt microparticles

Derevich I.V., Ermolaev V.S., Mordkovich V.Z., Solomonik I.G., Fokina A.Yu

в журнале International Journal of Heat and Mass Transfer, издательство Pergamon Press Ltd. (United Kingdom), том 121, с. 1335-1349 DOI - 2018 Scaled-up process for producing longer carbon nanotubes and carbon cotton by macro-spools

Mordkovich V.Z., Kazennov N.V., Ermolaev V.S., Zhukova E.A., Karaeva A.R.

в журнале Diamond and Related Materials, издательство Elsevier BV (Netherlands), том 83, с. 15-20 DOI - 2018 Catalytic 3D polymerization of C60

Mikhail Popov, Boris Kulnitskiy, Igor Perezhogin, Vladimir Mordkovich, Danila Ovsyannikov, Sergei Perfilov, Ludmila Borisova, Vladimir Blank

в журнале Fullerenes, Nanotubes and Carbon Nanostructures, издательство Taylor & Francis (United Kingdom), том 26, № 8, с. 465-470 DOI

- Статьи в сборниках

- 2018 Carbon Fiber-Reinforced Polyurethane Composites with Modified Carbon–Polymer Interface

Karaeva A.R., Kazennov N.V., Mordkovich V.Z., Urvanov S.A., Zhukova E.A.

в сборнике Proceedings of the Scientific-Practical Conference "Research and Development-2016", место издания Springer Cham, с. 415-420 DOI - 2012 Water Concentration Influence on Catalytic Growth of Carbon Nanotubes in a Suspended Bed Reactor

Mordkovich V.Z., Karaeva A.R., Khaskov M.A., Solomonik I.G., Mitberg E.B., Kulnitskiy B.A., Perezhogin I.A.

в сборнике MRS Fall Meeting, том 1407, с. 19-24 DOI

- Диссертации

- 2023 Кобальт-алюминий-цеолитные композиции и их каталитические свойства в реакции Фишера–Тропша

Кандидатская диссертация по специальностям 1.4.12 - Нефтехимия, 1.4.1 - Неорганическая химия (хим. науки)

Автор: Асалиева Екатерина Юрьевна

Научные руководители: Мордкович Владимир Зальманович, д.х.н., Булычев Борис Михайлович, д.х.н., проф., МГУ имени М.В. Ломоносова

Защищена в совете МГУ.014.7(02.06) МГУ имени М.В. Ломоносова, Химический факультет

Организация, в которой выполнялась работа: ФГБНУ «Технологический институт сверхтвердых и новых углеродных материалов», МГУ имени М.В. Ломоносова

Оппоненты: Никитин Алексей Витальевич, Лисичкин Георгий Васильевич, Бухаркина Татьяна Владимировна - 2021 ТЕРМИЧЕСКАЯ УСТОЙЧИВОСТЬ УГЛЕРОДНЫХ НАНОТРУБОК КАК КОМПОНЕНТА КОМПОЗИЦИОННЫХ МАТЕРИАЛОВ

Кандидатская диссертация по специальности 02.00.04 - Физическая химия (хим. науки)

Автор: Пушина (Жукова) Е.А.

Научный руководитель: Мордкович В.З., д.х.н.

Защищена в совете МФТИ ФЭФМ.02.00.04.001 при Московский Физико-технический Институт (национальный исследовательский университет) - 2021 Парциальное окисление природного газа как способ получения углерода с луковичной структурой

Кандидатская диссертация по специальности 05.17.07 - Химическая технология топлива и высокоэнергетических веществ (техн. науки)

Автор: Лугвищук Дмитрий Сергеевич

Научный руководитель: Мордкович В.З., д.х.н.

Защищена в совете РХТУ.Р.09 при ФГБОУ ВО «Российский химико-технологический университет имени Д.И. Менделеева»

Организация, в которой выполнялась работа: Технологический институт сверхтвердых и новых углеродных материалов

Оппоненты: Клушин Виталий Николаевич, Пешнев Борис Владимирович, Жагфаров Фирдавес Гаптелфартович - 2021 Катализаторы синтеза Фишера–Тропша, содержащие кобальт, цеолит и теплопроводящую добавку

Докторская диссертация по специальности 02.00.13 - Нефтехимия (хим. науки)

Автор: Синева Л.В.

Научные консультанты: Мордкович В.З., д.х.н., Лапидус А.Л.

Защищена в совете Д 002.222.02 при Институт органической химии РАН - 2019 Повышение эффективности процесса получения синтетических жидких углеводородов из природного газа

Кандидатская диссертация по специальности 05.17.07 - Химическая технология топлива и высокоэнергетических веществ (техн. науки)

Автор: Ермолаев Илья Сергеевич

Научный руководитель: Мордкович В.З., д.х.н.

Защищена в совете Д 212.204.08 при РХТУ им. Д.И.Менделеева

Ведущая организация: Федеральное государственное бюджетное образовательное учреждение высшего образования «Московский политехнический университет»

Оппоненты: Савостьянов Александр Петрович, Вахрушин Павел Александрович - 2018 Кобальтовые катализаторы синтеза Фишера–Тропша на основе катионных форм цеолитов

Кандидатская диссертация по специальности 02.00.15 - Кинетика и катализ (хим. науки)

Автор: Кульчаковская Екатерина Владимировна

Научный руководитель: Мордкович В.З., д.х.н.

Защищена в совете Д 002.222.02 при Институт органической химии РАН

Организация, в которой выполнялась работа: ФГБНУ ТИСНУМ, МГУ им. М.В. Ломоносова

Ведущая организация: Федеральное государственное бюджетное образовательное учреждение высшего образования «Российский государственный университет нефти и газа (национальный исследовательский университет) имени И. М. Губкина»)

Оппоненты: Арутюнов Владимир Сергеевич, Пешнев Борис Владимирович - 2017 Синтез Фишера–Тропша на кобальтовых катализаторах с высокой теплопроводностью

Кандидатская диссертация по специальностям 02.00.13 - Нефтехимия, 05.17.07 - Химическая технология топлива и высокоэнергетических веществ (техн. науки)

Автор: Грязнов К.О.

Научные руководители: Мордкович В.З., д.х.н., Третьяков В.Ф., д.х.н., проф.

Защищена в совете Д 212.131.08 при Московский технологический университет

Организация, в которой выполнялась работа: ФГБНУ ТИСНУМ, МИТХТ им. М.В. Ломоносова

Ведущая организация: ВНИИНП

Оппоненты: Савостьянов А.П., Елисеев О.Л. - 2017 Синтез Фишера-Тропша на кобальтовых катализаторах с высокой теплопроводностью

Кандидатская диссертация по специальностям 02.00.13 - Нефтехимия, 05.17.07 - Химическая технология топлива и высокоэнергетических веществ (техн. науки)

Автор: Грязнов Кирилл Олегович

Научные руководители: Мордкович В.З., д.х.н., Третьяков Валентин Филиппович

Защищена в совете Д 212.131.08 при Московский технологический университет - 2016 МОДИФИЦИРОВАНИЕ УГЛЕРОДНОГО ВОЛОКНА УГЛЕРОДНЫМИ НАНОСТРУКТУРАМИ

Кандидатская диссертация по специальности 02.00.21 - Химия твердого тела (хим. науки)

Автор: Урванов Сергей Алексеевич, к.х.н.

Научный руководитель: Мордкович Владимир Зальманович, д.х.н.

Защищена в совете Д 501.001.51 при МГУ имени М.В. Ломоносова, Химический факультет